Pile Load Test in UAE

A pile load test in UAE is a direct method of determining the ultimate geotechnical capacity of a pile. Dynamic load testing (PDA-measurement) is a fast and reliable way to evaluate the bearing capacity of a pile.

Under ordinary conditions, the Geo professional doled out to play out the examination can accumulate enough data to suggest a heap write and tip height that is equipped for supporting the required loads on the prescribed heap establishment. Notwithstanding, there are circumstances where subsurface strata are variable, problematic, or of such low quality that extra data is required so as to make strong heap establishment suggestions. In these circumstances, Static Pile Load Testing or potentially Pile Dynamic Analysis (PDA) will be prescribed. Data got from the testing and additionally PDA will be utilized to check plan suppositions or adjust establishment suggestions.

Faculty from Geotechnical Services, Foundation Testing Branch, perform Static Load Testing and PDA on Caltrans ventures. Once the testing is finished, composed reports outlining the discoveries are transmitted to the Engineer. In a perfect world, these tests would be performed in the Design Phase; be that as it may, they are frequently done in the Construction Phase.

Pile Load Test in UAE

- By installation of single crown of designed capacity

- By installation of successive crowns one over the other side for mega load tests

- By installation of reaction beams for uplift and compression load tests.

Our Valued Projects

Reasons for Pile Load Test in UAE and Pile Dynamic Analysis

Static Load Tests measure the reaction of a heap under a connected load and are the most precise strategy for deciding heap limits. They can decide a definitive disappointment heap of an establishment heap and decide its ability to help the heap without over the top or consistent dislodging. The reason for such tests is to confirm that the heap limit in the built heap is more prominent than the ostensible opposition (Compression, Tension, Lateral, and so on.) utilized as a part of the plan. The best outcomes happen when heap stack tests are performed in conjunction with Pile Dynamic Analysis (PDA). The tests give the Geo professional data expected to permit the utilization of a more “normal” establishment plan.

Static load tests might be suggested when heaps are introduced in soils with variable topographies or low quality soils and can be utilized to approve outline suppositions or to give adequate data to alter the plan tip heights. They are frequently suggested for Cast-In-Drilled-Hole (CIDH) heaps introduced in dubious ground arrangements as there is no different intends to decide limit. They give more precise data than can be acquired from heap driving equations and may exhibit that determined heaps can be securely stacked past the limits got from these recipes.

Heap stack tests are costly to perform yet offer some incentive to a structure. The FHWA Publication No. FHWA-SA-91-042, Static Testing of Deep Foundations, gives the accompanying suggestions on when to play out a heap stack test. They are as per the following:

When there is a potential for huge cost funds. Normally on expansive ventures with comparative strata and heap write.

- When the sheltered stacking condition is in question, because of impediments of an Engineer’s experience base, or surprising site or undertaking conditions.

- When soil or shake conditions fluctuate impressively starting with one bit of a venture then onto the next.

- When the plan stack is fundamentally higher than common outline loads.

- When time-related soil limit changes are foreseen (i.e. soil setup and unwinding.)

- To decide the length of precast grating heaps to maintain a strategic distance from joins.

- When new or problematic heap composes or establishment techniques are to be utilized.

- When existing heaps will be utilized to help another structure with heavier burdens.

- To acquire a solid incentive for pliable and horizontal heap obstruction.

- When, amid development, the heap conveying limit of the heap varies. fundamentally from what was anticipated from heap driving recipes and PDA.

In lieu of completing a static load test, PDA can be utilized to set up criteria for heap acknowledgment and to check outline suppositions. It can decide soil obstruction, pound effectiveness/execution, and worries in the heap amid driving. Caltrans hone is to utilize PDA to build up heap acknowledgment criteria for non-standard driven heaps up to 36 inch breadth. PDA in blend with static heap stack testing is utilized to build up heap acknowledgment criteria for driven heaps bigger than 36-inch distance across. Allude to Bridge Construction Memo 130-4.0, Pile Driving Acceptance Criteria.

The data acquired from the PDA can likewise be utilized by different projects to decide the bearing limit of the heap. Consolidating these outcomes with those from the heap stack test builds the precision while deciding the bearing limit.

Static Pile Load Test in UAE

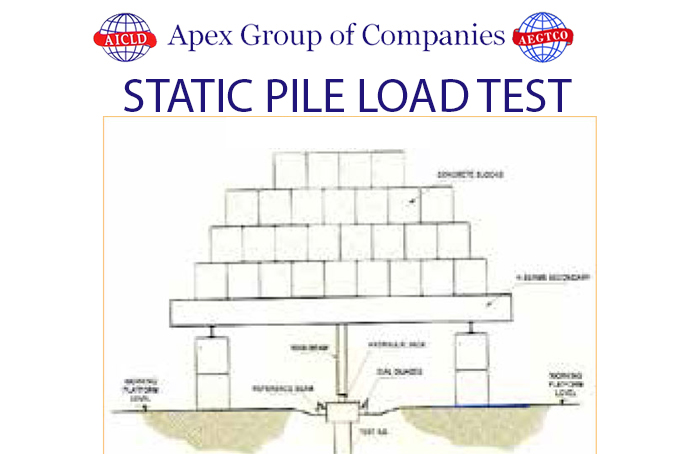

The static heap stack test gives the most precise sign of the limit of the set up heap. It is performed utilizing a response technique. The test strategy includes applying a pivotal load to the highest point of the test heap with at least one water powered jacks. The response constrain is exchanged to the grapple heaps that go into strain on account of a static load test in pressure; or into pressure on account of a static load test in strain. Different types of instrumentation are introduced onto the test and grapple heaps with the goal that an exact estimation of the test heap uprooting can be acquired. Repetitive frameworks are utilized to guarantee exactness of the different estimations.

A five-heap test gathering (four stay heaps and one test heap) is utilized for all static load tests in pressure and for most strain tests (Figure 8-1). Every so often, a three-heap test gathering (two stay heaps and one test heap) is utilized for static load tests in strain (allude to Appendix F, Pile Dynamic Analysis, Static Pile Load Testing and Field Acceptance Criteria). Burdens are connected in increases; regularly equivalent to 5% of the outline stack. Every augmentation of load is held for a foreordained time interim. The test strategy is led in agreeing with ASTM 1143, Procedure A: Quick Test. The heap limit acknowledgment or disappointment criteria will be dictated by the parameters built up by the structure plan and geotechnical build.

The Static Pile Load Test causes a disappointment along the dirt/heap interface. This disappointment for the most part happens a long time before a definitive auxiliary limit of the heap is come to. Once the test is finished, the heap is come back to a no-heap condition and can be fused into the establishment of a structure. The main perpetual impact of a heap stack test on a determined heap is the descending dislodging of the test heap. A similar impact would be accomplished if a heap pound drove the heap the extra separation. The past explanation, while valid for driven heaps, may not be the situation for Cast-in-Place heaps, and shake attachments specifically, as these heaps won’t act the same once the bond between the solid and the dirt has been broken.

Once the heap stack testing is finished, staff from the Foundation Testing Branch aggregate and audit the heap test information. The test information is utilized to deliver a plot of load versus heap relocation. A definitive limit of the test heap is resolved utilizing graphical or investigative methodology. An outline report is then sent to the Engineer, alongside any prescribed changes or adjustments to the plan.

Static Pile Load Testing surpasses the benchmarks expressed in ASTM D1143, Procedure A: Quick Test, for static load testing in pressure, and ASTM D3689 for static load testing in strain. Both the pressure and strain stack tests each take roughly 4 to 8 hours to finish.

The Foundation Testing Branch has four static pivotal heap stack test frameworks of differing greatest load limit:

- 1,000,000-pound Load Test System

- 2,000,000-pound Load Test System

- 4,000,000-pound Load Test System

- 8,000,000-pound Load Test System

Solicitations for Static Load Tests are made to the Foundation Testing Branch on the Pile Load Test (PLT) Request Form. A duplicate of this shape is incorporated into Appendix F, Pile Dynamic Analysis, Static Pile Load Testing and Field Acceptance Criteria, and is accessible for download.1

Pile Dynamic Analysis (PDA)

The dynamic investigation alludes to the utilization of a gadget called the Pile Driving Analyzer. The Pile Driving Analyzer comprises of a compact PC that gathers and investigates strains and increasing speeds estimated by instrumentation joined to the heap being driven.

The Pile Driving Analyzer administrator inputs parameters identified with the physical qualities of the heap before the heap examination starts. Information to portray the encompassing soil and its damping opposition is likewise entered. The Pile Driving Analyzer is fit for investigating the pressure wave created along the length of the heap by each blow of the sledge amid the driving task. By breaking down the state of the wave follow, the Pile Driving Analyzer can quantify heap stresses created amid driving. Amid establishment, harm to a heap can frequently be recognized by the Pile Driving Analyzer. The information recovered amid the investigation can be utilized to decide the area or profundity of a break in a solid heap and to the point of locking in a steel heap.

The Pile Driving Analyzer precisely measures the vitality conveyed to the heap amid driving. This vitality rating can be contrasted with the producer’s appraised an incentive to give a sign of the sledge’s genuine execution efficiencies. Low or irregular conveyance of vitality to the heap may show issues, for example, a pre-start issue inside the sledge, wasteful mallet ignition, misalignment of the devotee or head protector, or the utilization of an unseemly heap pound pad.

Heap Dynamic Analysis is accepted to be solid for heaps determined in granular soils. For better grained soils, for example, sediments and muds, this strategy might be less solid on the grounds that these dirts offer essentially bigger damping protection from the heaps amid driving and might be hard to demonstrate precisely.

Data recovered by the Pile Driving Analyzer is additionally used to anticipate a heap’s static load limit. The dynamic investigation is performed on generation heaps as determined in the uncommon arrangements and on the test or potentially stay heaps utilized for a Static Load Test if appropriate. Heaps observed utilizing the Pile Driving Analyzer are typically determined a foreordained separation over the predetermined tip before the investigation starts. Around then, the driving prevents to permit work force from the Foundation Testing Branch to connect the essential instrumentation to the heap. The instrumentation is joined 1-1/2 to 2 heap widths from the highest point of the heap. Once introduced, the Contractor resumes driving the heap. The initial couple of blows are done gradually to permit the Pile Driving Analyzer administrator to guarantee that the instrumentation is appended accurately and that the information is transmitted to the Pile Driving Analyzer PC. Driving at that point proceeds until the point when the predetermined tip rise is come to. In a few soils, commonly strong soils, the heaps may increment in limit or set-up after some time. At the point when this is foreseen, the tip of the heap is left around one foot over the predetermined tip height.

After the set-up period has slipped by, the heap is prepared for a re-drive. The time allotment for set-up is typically medium-term yet can be longer. Prior to the re-drive, Pile Driving Analyzer instrumentation is indeed connected to the heap, and the last foot of the heap set apart in additions of one tenth of a foot. The heap is hit for a couple of hits to ensure that the instrumentation is working appropriately. The heap is then determined for a few inches or the rest of the one-foot length. The limit of the heap is resolved from PDA or through heap driving conditions. The new bearing limit is contrasted with the one preceding set-up to decide the expansion in limit over that timeframe. The idea of heap limits expanding amid a set-up period is talked about completely in Chapter 7, Driven Piles.

Under typical conditions, dynamic investigation is utilized as a part of conjunction with static load testing to decide the sufficiency of establishment heaps. Similarly as with Static Load Testing, work force from the Foundation Testing Branch is allocated the duty regarding performing PDA on Caltrans ventures. Solicitations for PDA are submitted to the Foundation Testing Branch on the Pile Dynamic Analysis Test Request Form. A duplicate of this shape is incorporated into Appendix F, Pile Dynamic Analysis, Static Pile Load Testing and Field Acceptance Criteria, and is accessible for download.

Most auxiliary designers have without a doubt scrutinized the benefits of consolidating advanced basic examination with establishment proposals from geotechnical advisors that give off an impression of being minimal superior to anything general “dependable guideline” values with expansive and obscure components of security.

The need of less exact establishment suggestions lies mainly in the heterogeneity inalienable in characteristic soil and in the frequently experimental nature of geotechnical outline. While the building properties of development materials are generally very much characterized and unsurprising, the designing properties of soil and shake are normally anticipated that would fluctuate from area to area.

Various geotechnical plan approaches are construct incompletely with respect to hypothesis and somewhat on observational test outcomes. Albeit nearby experience and comprehension of the inceptions of geologic materials at venture locales can help approve the pertinence of particular plan approachs, without execution testing, the geotechnical build frequently has no response however to depend on traditionalist components of security that endeavor to represent different vulnerabilities.

Site-particular execution tests are normally not financially savvy in many ventures and utilizing vast components of security rather is generally a more sparing method for moderating the danger of vulnerabilities. Be that as it may, for specific tasks, execution testing of establishments may demonstrate financially savvy and here and there essential. Execution testing empowers more forceful geotechnical plan in light of the fact that genuine components of wellbeing can be checked. More forceful geotechnical configuration as a rule brings about a diminishment of the cost of establishments. What’s more, execution testing might be essential for venture locales with surprising geologic materials or materials not at all like those for which exact outline data is accessible.

Present day heap establishments are utilized as a part of zones where less expensive shallow spread type establishments are not esteemed plausible (heap establishments are normally used to control foreseen settlement or to reach out to equipped bearing materials). Since heap establishments are regularly used to help heavier and additionally basic structures on minimal geologic materials, execution testing of heap establishments (heap stack testing) is moderately normal. Heap stack tests are for the most part performed to either demonstrate that heaps are fit for managing the outline stack or to acquire natty gritty data that will empower a more effective plan.

Sorts OF Pile Load Test in UAE

Static and dynamic heap stack tests can be performed on bored or driven heaps to assess either hub or horizontal limits. Static tests comprise of stacking heaps and estimating diversion. Dynamic tests endeavor to acquire static heap limits by and large utilizing pressure wave examinations of heap redirection caused by powerful loads. The common means and strategies utilized as a part of static tests and different unique heap stack test techniques, which are by and large less demanding to perform and more conservative, are examined in the segments beneath.

As said before, heap stack tests are for the most part performed to either demonstrate that heaps are equipped for maintaining a definitive plan stack (“confirmation test”) or to acquire nitty gritty data that will empower a more proficient outline (“stack disfigurement test”). For a proof test, a test heap is stacked to a definitive plan stack (admissible outline stack times the factor of wellbeing) and the avoidance is estimated at the heap head. In the event that the avoidance is inside permissible levels, the test has “demonstrated” that the heap is satisfactory. Confirmation tests are for the most part performed amid development as the heaps are introduced.

Load-distortion tests, then again, are typically performed amid the plan period of tasks preceding real development. For these tests, a heap is ordinarily tried to disappointment and misshapening (and regularly stretch) is estimated at a few focuses along the heap shaft and at the heap tip and also at the heap head. The point by point stack twisting information got permits more effective plan by decreasing the factor of security through better comprehension of the site-particular properties.

Types of Static Pile Load Test in UAE

Regular

Regular static heap stack tests in bored or driven heaps comprise of developing a response outline around the test heap and incrementally stacking the heap, as a rule with a water powered jack. The response outline is secured by no less than two response heaps. The test stack is estimated with stack cells and heap head twisting is estimated with strain measures and studying gear.

For stack disfigurement tests, strain checks imbedded inside the heap might be utilized to decide the heap conveyance along its length. Elevate and horizontal load tests are performed by changing the response edge and stacking (jacking) the heap the coveted way. Albeit exorbitant and tedious, traditional load test by and large give the most dependable execution information in light of the fact that the stacking technique is like administration stacking.

Osterberg Cells

For penetrated heaps, stack tests utilizing Osterberg cells might be a more financially savvy other option to customary static load tests. Osterberg cells are basically huge measurement pressure driven jacks with worked in stack cells that are thrown inside the heap with twin response plates comparative in distance across to the penetrated heap at the best and base of the phone. Development is estimated utilizing strain checks and reference bars detached from strain (sleeved) reaching out from the highest point of Osterberg cells to the ground surface. Strain checks are likewise used to quantify the opening of the cell.

Osterberg cells are normally not utilized for elevate testing in light of the fact that customary inspire tests are for the most part more affordable much of the time. In any case, Osterberg cells are practical for pressure and horizontal load tests since response heaps or stays are not required.

Single cells are normally utilized for pressure confirmation tests. A heap cell is thrown close to the base of the heap and extended to get load and avoidance information. Some translation of the information is required on the grounds that the test stacking is uniquely in contrast to benefit stacking. Amid the test, the cell is extended close to the base of the pole, causing inspire over the cell and settlement beneath the cell.

Since the phone loads are opposed by shaft opposition over the phone and heap end bearing beneath the phone, stack twisting information for the heap tip and heap shaft can be gotten autonomously. Numerous phones can be thrown inside a test heap to detach end-bearing and shaft grating impacts or to assess directional impacts of shaft contact.

Dynamic Pile Load Test in UAE

The as of now utilized unique heap testing procedure was created from inquire about subsidized by the Ohio Department of Transportation and the Federal Highway Administration at the Case Institute of Technology in Cleveland, Ohio. Utilizing estimations of strain and speeding up and the standards of wave mechanics, dynamic test techniques are utilized to assess static heap limit, examine heap honesty, and assess heap driving frameworks. There are two sorts of dynamic heap testing: substantial strain strategies and low-strain techniques.

Low-Strain Methods

Low-strain techniques are regularly performed utilizing hand-held mallets that measure heap top speeds and are utilized essentially to assess respectability and length of solid heaps. Oddities in the speed record are utilized to assess heap honesty. Though low-strain techniques to review heap honesty are restricted to profundities of around 20 times the heap measurement, substantial strain strategies can ordinarily be utilized to assess the whole length of heaps.

Expansive Strain Methods

Expansive strain techniques are utilized solely for driven heaps to assess the driving framework and also to estimate static pivotal heap limit. Strain checks and accelerometers are introduced close to the highest point of the heaps and estimations are taken amid heap driving. Huge strain dynamic heap testing is ordinarily performed amid the marker heap program (the pointer heap program is a field trial of the chose driving mallet and framework to assess the driving criteria, driveability, and creation rate). Since the cost of introducing the strain checks and accelerometers and observing the estimations is moderately economical contrasted with the aggregate cost of the pointer heap program, dynamic heap testing is a financially savvy method for advancing the driving framework and assessing static heap limit. For driven heaps, advancement of the driving framework might be as essential as evaluating heap limits.

The estimations of strain are changed over to drive and the estimations of increasing speed are changed over to speed for contribution to dynamic obstruction conditions to assess static heap limits. The most prominently utilized unique opposition condition is the Case Method (Goble et al., 1975).

A particular mallet blow can be examined utilizing the Case Method and a dirt model to appraise the pole grating, end bearing, unique damping components, and soil firmness. A PC program called CAPWAP® for Case Pile Wave Analysis Program from Goble, Rausche, Likins and Associates, Inc. can be utilized to play out this examination. The pressure and inspire static heap limits would then be able to be evaluated.

Albeit dynamic testing can used to gauge static heap limit with respect to bored heaps, preparing a heap driving sledge and apparatus is typically not financially savvy.

Pseudo-Static Load Tests

Test approaches that join the practicality of dynamic strategies with stacking like traditional load tests incorporate the Statnamic® test and the Pile Load Tester. Albeit the two techniques are like unique tests in that test heaps are affect stacked, these strategies forestall wave engendering impacts by spreading the transmitted vitality over a more extended period. Essentially to static load tests, these strategies create stack distortion (settlement) bends.

Satanic

Pressure and sidelong heap limits can be assessed with the Statnamic test strategy. The test technique comprises of quickening response masses toward the path inverse to the test stack course by touching off force fuel. A heap cell measures the heap and the misshapening of is estimated utilizing reviewing hardware. For security reasons, response masses are encased inside a metal packaging loaded with rock or another materials used to hose the arrival fall of the response masses.

Heap Load Tester

A heap stack analyzer must be utilized to assess pressure heap limits. For this test technique, an extensive mass is dropped over the test heap. The mass with the wound springs is dropped onto a blacksmith’s iron resting on the test heap. On finish of the upward stroke (ricochet), the mass is gotten in its most noteworthy position by water driven clasps. The heap is estimated utilizing a heap cell and disfigurement is estimated utilizing reviewing gear.

The effect of the falling mass is diminished and the vitality transmission time is stretched out finished a more drawn out day and age by the utilization of overwhelming wound springs appended to the base of the mass. The springs empower the presentation of a moderate rising, dependable hit to the heap without causing dynamic impacts (wave spread) exhibit amid dynamic load testing; wave proliferation confuses understanding. The springs spread the effect wave over around 200 to 400 milliseconds.

CONCLUSION

More point by point and exact geotechnical establishment proposals can be produced utilizing the heap stack testing techniques portrayed previously. The extra venture required to secure the more exact data regularly pays vast profits in material costs funds. In any event, confirmation testing of heap establishments can give extra genuine feelings of serenity that the normal limits in configuration are in truth accessible in the field.

Types of LOAD TEST METHODS

Dynamic Load Test Methods

Roughly 160 powerful heap stack tests were performed to assess heap limit, driving burdens, and sledge execution amid the establishment of test heaps and generation heaps. The information introduced in this report were acquired from venture documents. (See references 25, 26, 27, 28, 29, 30, 31, 32, 33, 34.)

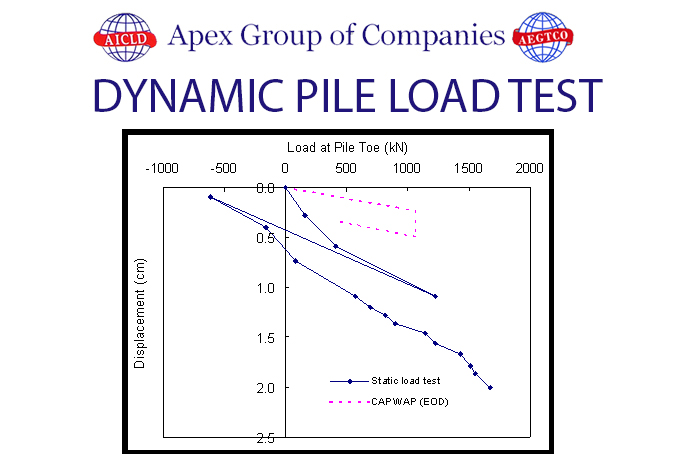

The PDA was utilized to record, digitize, and forms the power and speeding up signals estimated at the heap head. These signs were utilized to evaluate static limit utilizing the Case Method, an improved field strategy for assessing heap limit, and the more thorough CAPWAP. The dynamic load test comes about talked about in this report are essentially from the CAPWAP investigations. A portrayal of the basics of dynamic testing, including CAPWAP, is introduced in Design and Construction of Driven Pile Foundations (Federal Highway Administration (FHWA) report no. FHWA-HI-97-013).(17) The dynamic testing was done when all is said in done understanding with venture particulars segment 940.62.C,(14) Dynamic Load Tests, and D4945-89 of the American Society for Testing and Materials (ASTM). D4945-89 is entitled “Standard Method for High Strain Testing of Piles.”(35)

Apex is an iterative bend fitting strategy where the heap reaction decided in a wave condition show is coordinated to the deliberate reaction of the real heap for a solitary sledge blow. The heap demonstrate comprises of a progression of nonstop sections and the aggregate obstruction of the inserted part of the heap is spoken to by a progression of springs (static opposition) and dashpots (dynamic opposition). Static obstruction is figured from a glorified elastoplastic soil demonstrate, where the tremor parameter characterizes the dislodging at which the dirt changes from flexible to plastic conduct. The dynamic opposition is planned utilizing a gooey damping model that is a component of a damping parameter and the speed.

In the first place, the powers and increasing speeds following up on the genuine heap amid starting effect are recorded with a strain check and accelerator mounted at the heap head. The deliberate speeding up is utilized as contribution to the heap demonstrate alongside sensible evaluations of soil opposition, shake, and damping parameters. The power time motion at the heap head is computed utilizing the model and is contrasted with the deliberate power time flag. The dirt obstruction dissemination, shudder, and damping parameters are thusly altered until the point when understanding is come to between the deliberate and ascertained signs. A case of a correlation between a deliberate and computed constrain motion from one of the test heaps is appeared in figure 20. Once a worthy match is accomplished, the arrangement yields a gauge of extreme static limit, the conveyance of soil obstruction along the heap, and the shake and damping parameters.

Static Load Test Methods

Static load tests were performed amid the test period of each agreement to confirm the plan suppositions and load-conveying limit of the heaps. Obvious bars introduced at different profundities inside the heaps were utilized to assess the heap exchange conduct of the heaps as to the encompassing soil and bearing stratum. The static tests were completed when all is said in done understanding with venture details segment 940.62.B.4,(14) Short Duration Test, and the ASTM’s D1143-81, which is entitled “Standard Test Method for Piles Under Static Axial Compression Load.”(36) The static load test information displayed in this report were acquired from the task records. (See references 37 through 50.)

Static burdens were connected and kept up utilizing a water driven jack and were estimated with a heap cell. A run of the mill stack test game plan is appeared in figure 21. Response to the jack stack is given by a steel outline that is connected to a variety of steel H-heaps situated no less than 3 m far from the test heap. Heap head redirection were estimated with respect to a settled reference shaft utilizing dial checks. Obvious estimations were made in reference to the heap head or the reference shaft utilizing dial measures. Heap head and obvious redirection information were recorded for each stacking augmentation.